Preventing unexpected bearing failures in your production line is now possible. At the same time, you can improve energy efficiency by utilizing HCP Sense technology. This innovation continuously monitors the load and lubrication film inside the bearing in real-time. Additionally, it offers two different integration models.

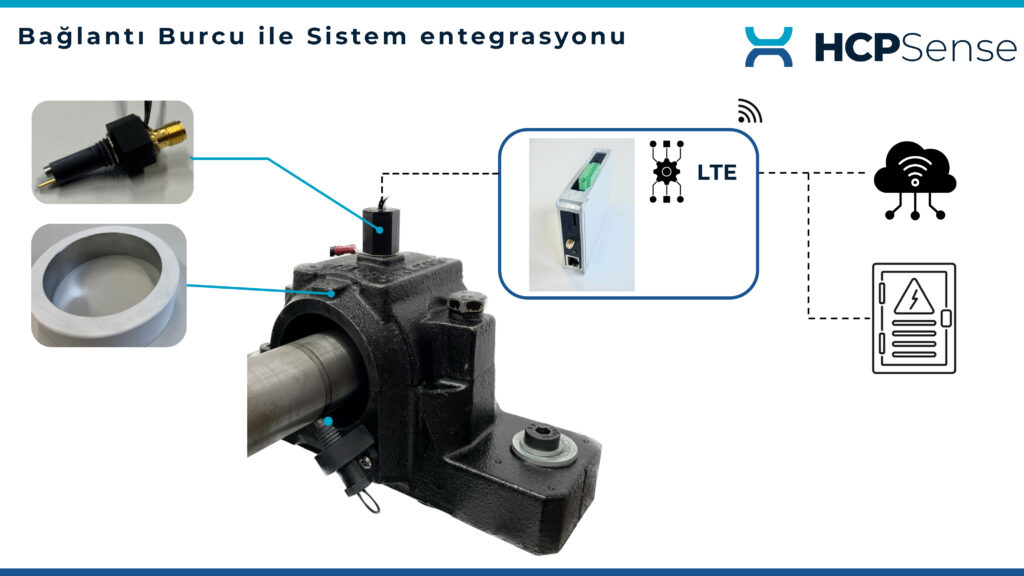

🔩 Integrated Solution with Sleeve (Brush-Based)

- Features a classic brush structure.

- Allows for fast and easy installation.

- Can be integrated into existing bearing systems with ease.

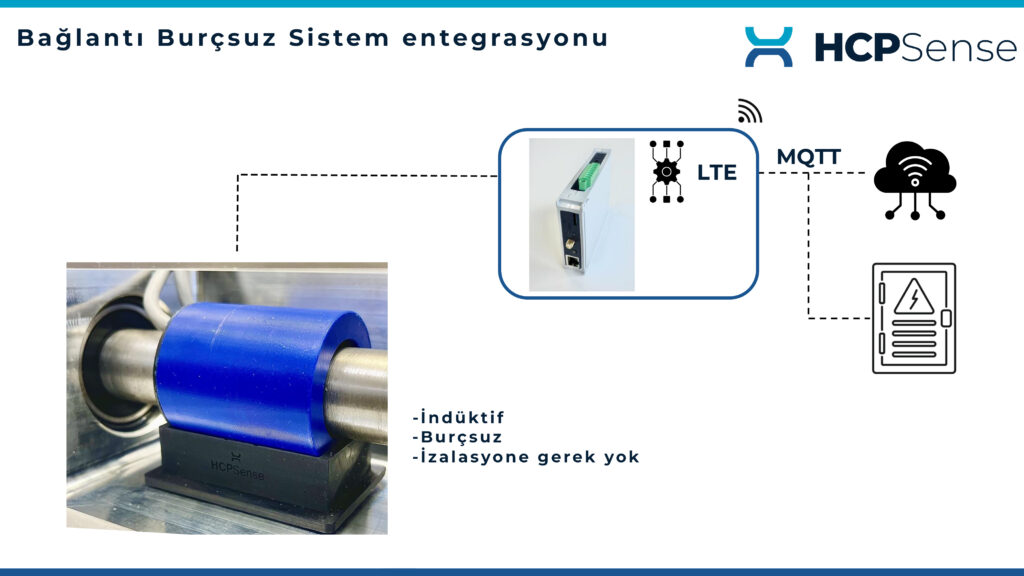

🌀 Sleeve-Free (Inductive) Integration

- No mechanical sleeve required – non-contact measurement.

- Eliminates the need for additional insulation.

- Simplifies wiring and reduces maintenance needs.

🎯 Common Advantages

Both solutions offer the following benefits:

- Minimizes the risk of unplanned downtime.

- Detects installation errors during assembly.

- Optimizes load distribution.

- Extends the lifetime of your equipment.

- Reduces energy consumption and lowers operational costs.

📘 Guides and Technical Resources

For more information, please visit the following websites:

📩 Contact Us

For technical support or presentation requests, feel free to get in touch: